Built for Speed, Consistency, and Efficiency

Our inline digital label production solutions deliver true one-pass, print-to-finish manufacturing - seamlessly combining printing and converting into a single, continuous workflow.

But successful label production is about more than hardware. It demands close collaboration, deep technical alignment, and the right OEM partnerships.

That’s why we work closely with leading press manufacturers such as HP Indigo, SCREEN, Domino, Konica Minolta, Epson, Xeikon, and others. These partnerships enable us to develop finishing solutions that integrate seamlessly with digital presses, deliver proven reliability, and create measurable production value.

Developed in collaboration with GM, the system pairs high-performance digital printing with precision inline finishing, eliminating offline processes, secondary handling, and unnecessary downtime.

Labels are printed, finished, and rewound in one uninterrupted pass, enabling faster turnaround times, reduced waste, and consistent, repeatable quality across both short and long production runs.

True Inline Workflow

All production stages operate within a single web path. Printing, converting, and finishing are fully synchronised, allowing jobs to run continuously without stopping, rewinding, or changing rolls between processes.

Inline workflow advantages include:

By keeping finishing perfectly aligned with print output, the system prevents bottlenecks and maximises overall uptime.

Inline Finishing Powered by GM

GM inline finishing modules are engineered specifically for digital press environments, functioning as a natural extension of the press rather than a separate system. Finishing operations are performed inline and in register, ensuring accuracy and consistency from start to finish.

Inline finishing capabilities include:

Labels exit the line fully converted and ready for delivery—no offline processing required.

Designed for Modern Label Production

With a compact footprint, broad media compatibility, and production speeds matched to inline finishing performance, this solution is ideal for converters looking to increase productivity without adding complexity.

The platform supports:

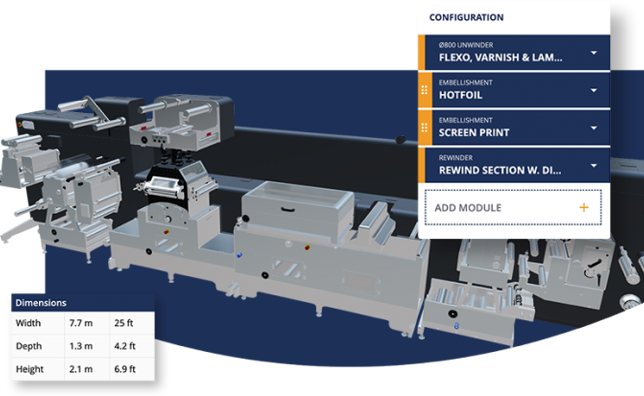

Its modular architecture allows converters to start with essential finishing functions and expand over time, maintaining a consistent workflow as business needs evolve.

Inline or Standalone - built for Real-World Flexibility

Designed for true inline, one-pass production, the system also allows inline or standalone operation. Each module can run independently or as part of the fully integrated line, giving converters the freedom to adapt production to job requirements, capacity planning, or specialised workflows.

A Proven Inline Production Platform

By integrating GM finishing technology into a fully inline digital production environment, converters gain a scalable, reliable solution built for real-world performance. The result is a balanced production line where quality, efficiency, and flexibility work together seamlessly—delivering maximum value from print to finished roll.

Contact us to learn how inline finishing with GM technology can optimise your label production workflow.

|

Hybrid finishing performance A flexible hybrid solution delivering consistent, high-quality results for both short and long runs. |

|

|

Automated operation Fast setup, smooth changeovers, and minimal waste with reduced operator intervention. |

|

|

Addded value for customers Enable premium labels with precision die cutting and inline flexo varnish and coatings. |

|

|

OEM integration powered by GM Die cutting and flexo stations developed and powered by GM Finishing, ready for inline production and workflow integratio |

|

13 January 2026

14 January 2026

14 January 2026

13 January 2026

13 January 2026

14 January 2026

Try out our 3D product configurator and customize your finishing line according to your specific preferences and needs.

Whether you do the printing or make the printers, we know that finishing is just the start of a great

brand experience for your customers.

Never hesitate to contact us for any label finishing advice or for an offer.

Contact us at:

Email: sales@gm.dk

Phone: +45 4581 2300