DC550Flex is built for professional label printers with the need for a complete and versatile solution in high-volume digital printing.

DC550Flex is an efficient and economical label finisher that is built with the same components as the DC550Flex+ and comes with handy options like format-free semi-rotation spot varnish, semi-rotation die-cutting, slitting, and dual rewind.

This modern platform ensures quick setup

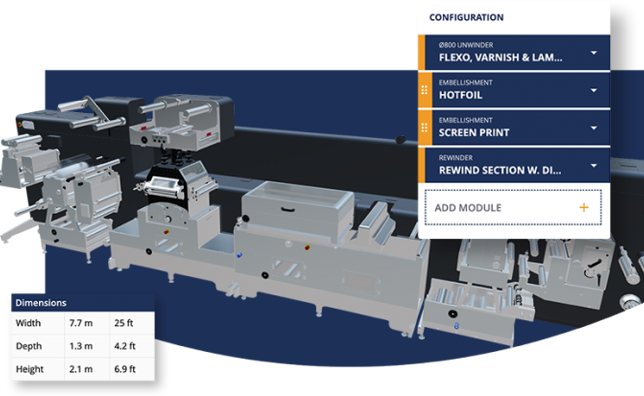

and flexibility along with an industry-leading user interface that gives the operator a graphical representation of the machine configuration and production flow.

Upgrade your production with value options like Turret rewinding, in-register lamination (MultiLayer), AutoKnives or Quick CrushKnives, FastStrip, Corona, web clean, back scoring & inline buffer.

Finally, DC550Flex is Industry 4.0 certified and prepared for in-line operation with all major digital presses.

This modular finishing platform will transform your production to the next level!

|

Superior end-results A cost-efficient label finisher built for volume production of added-value labels, like multi-layer labels. |

|

|

Automated operation Label production on this flexible and modern platform delivers quick setups and minimal waste. Improve productivity with less human intervention. |

|

|

Value for customers Create more value for your customers with foiling, spot varnish, and lamination. |

|

|

CERM increases efficiency GM converters are ready for integration with all digital label presses for full inline production. The possibility of integration with the CERM system increases efficiency and automates the workflow at all levels of production. |

|

Try out our 3D product configurator and customize your finishing line according to your specific preferences and needs.

02 May 2025

17 January 2024

02 April 2020

| Specifications | Metric | Imperial |

|---|---|---|

| Web width | 50 - 550 mm | 2 - 22” |

| Substrate | 50 - 200 µm | 2 - 8 pt. |

| Die Station | ||

| Max semi-rotary speed | 120 m/min | 394 ft/min |

| Max full-rotary speed | 130 m/min | 426 ft/min |

| Die plate size (repeat) | 50 - 558,8 mm | 2 - 22” |

| Unwinder | ||

| Diameter max. | 850 mm | 33.5” |

| Core diameter | 76,2 mm | 3” |

| Rewinder | ||

| Diameter max. on dual-shaft | 700 mm | 27.5” |

| Diameter max on Turret | 450 mm | 17.5” |

| Standard core diameter | 76,2 mm | 3” |

| Semi-rotary Flexo Station - Flower Style | ||

| Print cylinder size | 228,6 - 635 mm | 9 - 25” |

| Spot varnish with digital sensor register control and slow run - included | ||

| Slitting Station | ||

| Knife type | Pneumatic Quick CrushKnives, Quick Set Shear Knives, razor knives or AutoKnives | |

| Minimum distance Quick Crush | 21,5 mm | 0.85" |

| Minimum distance shear | 14 mm | 0.55” |

| Minimum distance AutoKnives | 15,5 mm | 0.61” |

| Dimensions | ||

| W x D x H | 5.90 × 2.24 × 1.66 m | 19.35 × 7.35 × 5.44 ft |

Whether you do the printing or make the printers, we know that finishing is just the start of a great

brand experience for your customers.

Never hesitate to contact us for any label finishing advice or for an offer.

Contact us at:

Email: sales@gm.dk

Phone: +45 4581 2300