Revolutionize Your Production

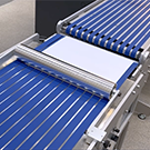

Elevate your production process with the RS350, our cutting-edge Rotary Sheeter designed to transform rolls into sheets with unparalleled precision and speed. Engineered to meet the highest standards, this state-of-the-art module ensures efficiency and quality in every operation.

Applications

Whether you are producing calendars, photobooks, or intricate die-cut labels, the RS350 Rotary Sheeter is the ultimate solution. Its advanced technology and user-friendly features make it the perfect choice for various sheeting requirements.

Integration and Operation

The RS350 can be operated as a standalone module with its own unwind system, offering you complete autonomy in your production line. Alternatively, it can be seamlessly integrated with any GM DC series finisher, providing a cohesive and efficient workflow. This flexibility ensures that the RS350 can be tailored to fit the specific needs of your production process.

Experience the next level of rotary sheeting with the RS350. Its combination of speed, precision, and versatility makes it an indispensable asset for modern production lines. Transform your operations and achieve superior results with the RS350 Rotary Sheeter.

|

Ultra-Fast Performance Experience the blazing-fast sheeting capabilities of the RS350. Its high-speed operation significantly enhances productivity, making it ideal for high-demand production environments. |

|

|

Standard Sheeting Plates The RS350 is designed to use conventional die-cutting plates, ensuring a seamless integration into your existing setup. This feature eliminates the need for specialized tools, reducing setup time and operational costs. |

|

|

Servo Driven, Format “Free” Sheeting One of the standout features of the RS350 is its servo-driven, format-free sheeting capability. This innovative design allows you to switch between different sheet sizes without the need to change the cylinder, offering unmatched flexibility and ease of use. |

|

|

Versatile Cutting Options The RS350 provides versatile cutting options, enabling you to cut to size or to a specific printing mark. This adaptability makes it suitable for a wide range of applications, from calendars and photobooks to die-cut labels. |

|

24 June 2024

| Specifications | Metric | Imperial |

|---|---|---|

| Web width | 50/ 350 mm | 2/ 13.8” |

| Substrate thickness | 50/ 350 µm | 2/ 13.8 pt. |

| Die station sheets with single side conveyor | ||

| Die cylinder | 304,8/ 711,2 mm | 12/ 28” |

| Full-rotary speed | 100 m/ min | 328 ft/ min |

| Variable speed (up to) | 50 m/ min | 164 ft/min |

| Sheet max size (variable speed) | 2000 mm | 79” |

| Sheet min size (variable speed) | 150 mm | 6” |

| Die station labels (Optional) | ||

| Die cylinder | 304,8/ 711,2 mm | 12/ 28” |

| Full-rotary speed | 100 m/ min | 328 ft/ min |

| Web path length | ||

| Power/ Air | 3 X 400V + N + PE, 32A / 6 bar. Tube dimension ø8mm | |

| Lak current | 300mA RCCB type B | |

| Patch cable internet connection with open ports 80 and 433 for outgoing connections. | ||

Whether you do the printing or make the printers, we know that finishing is just the start of a great

brand experience for your customers.

Never hesitate to contact us for any label finishing advice or for an offer.

Contact us at:

Email: sales@gm.dk

Phone: +45 4581 2300