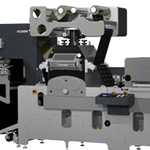

The DC350Nano is the most compact unit in GM’s series of label-finishing machines. It Is built on the same rock-solid die-cut unit as our biggest DC350 unit. A solid 20mm metal frame ensures a vibration-free basis for the four large servo motors that drive the web. The DC350Nano can be set up as an inline extension to a digital label press, allowing the web to continue directly into the converter from the digital press or as a standard offline unit. With semi-rotary die cutting, lamination, and a genuine pneumatic knife box with crush knives, it offers all you need for short-run label production. If required, the DC350Nano can work as a “Blanco” label die cutter as well.

The DC350Nano has all you need to make labels. Lamination, die-cut, slit & rewind as standard. Optional GM VPN GATEWAY, inline buffer module, Gap Master Kocher+Beck, advanced stripping roller system, and extra Mark Reader.

Very easy and quick print-to-cut registration – no station movement or mechanical setup required. An optional mark reader placed between the web guide and die-cut station determines the repeat minimizing the waste.

Adjustable repeat lengths from 2-22”; line speeds up to 45 m/min semi-rotary and 130 m/min full-rotary.

The large graphical touch display shows the web-up and all functions clearly in the local language.

Ensures accurate processing over a wide range of substrates.

This compact design fits in any print shop, measuring only 1,6 x 1,6 x 1,7 m.

The GM VPN GATEWAY enables remote service and support of GM machines through a unified, uninterrupted, and secured internet connection. It establishes access to the Internet through the firewall of the existing wired network infrastructure to provide remote access for on-demand, real-time servicing of GM equipment.

|

Inline or offline DC350Nano can be set-up as an inline extension to a digital label press, allowing the web to continue directly into the converter from the digital press or as a standard offline unit. |

|

|

Solid as a rock DC350Nano is built with the same smoothness in design and craftsmanship as our high-end DC350Flex series. |

|

|

Minimum waste The compact design in the DC350Nano ensures a very quick print-to-cut registration, hence minimum waste. |

|

|

Works inline with hotfoil DC350Nano produces highly embellished labels with the use of hot stamping and embossing. |

|

04 February 2025

03 July 2024

29 October 2020

| Specifications | Metric | Imperial |

|---|---|---|

| Web width | 50 - 350 mm | 2 - 13.8” |

| Substrate | 50 - 200 µm | 2 - 8 pt. |

| Die Station | ||

| Semi-rotary speed | 45 m/min | 148 ft/min |

| Full-rotary speed | 130 m/min | 426 ft/min |

| Die plate size (repeat) | 50 - 558,8 mm | 2 - 22” |

| Unwinder | ||

| Diameter max. | 500 mm | 19.7” |

| Core diameter | 76,2 or 152,4 mm | 3 or 6” |

| Rewinder - standard single-shaft | ||

| Diameter max. | 400 mm | 15.7” |

| Core diameter | 76,2 mm | 3” |

| Slitting Station | ||

| Knife type | Pneumatic crush | |

| Minimum distance crush | 12,7 mm | 0.5” |

| Dimensions | ||

| W x D x H | 1,6 x 1,6 x 1,7 m | 5.2 x 5.2 x 5.6 ft |

"

In January the company invested in a DC350NANO finishing unit from GM. The process from installation and training to running in full production was a very smooth transition.

"

A new customer, Nemprint A/S of Aarhus, Denmark, has acquired a DC350NANO, adding capacity in order to meet increasing customer demands.

"

US label manufacturer Rival Branding has invested in a GM DC330NANO converting unit as an all-in-one finishing solution for its Epson SurePress L-4533 digital inkjet label press. The new GM semi-rotary die-cutting converter has replaced a web-fed plotter die-cutter and significantly improved efficiency and quality.

Whether you do the printing or make the printers, we know that finishing is just the start of a great

brand experience for your customers.

Never hesitate to contact us for any label finishing advice or for an offer.

Contact us at:

Email: sales@gm.dk

Phone: +45 4581 2300