You have only seconds to capture a consumer’s attention to get them to notice your bottle, pick it up, and ultimately purchase it.

The DC350Flex Premium will make your labels stand out in a sea of wine options.

DC350Flex Premium line is a finishing line that provides the best in fast and highly automated wine label finishing.

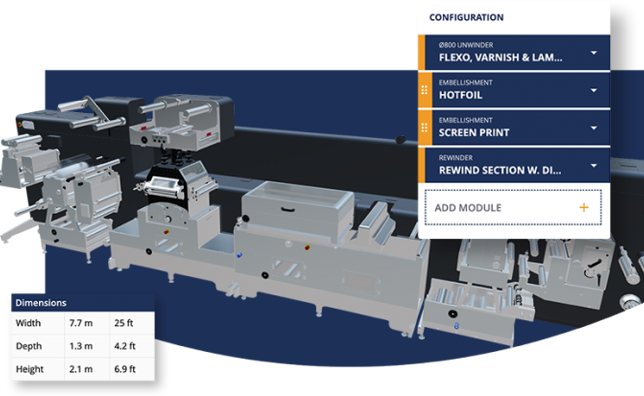

Featuring high-speed, hot-foil, screen varnish, semi-rotary flexo varnishing, and die-cutting as standard, this modular platform can be easily upgraded with value-added options like digital embellishment DVM350), multilayer label, laser die cutter, and much more.

The DC350Flex Premium platform is born to be modular, so if the market changes, new modules can be retrofitted quickly. Even third-party technology, such as a digital spot varnish module, can be integrated for true hybrid production.

Bespoke client options are available on the PLUS series.

Finally, DC350Flex Premium is Industry 4.0 certified and prepared for in-line operation with all major digital presses.

This wine label finishing platform will take your label production to the next level!

|

Fast with tension control Fast and heavy-weight hot foil unit applies up to 50-ton. Servomotors on unwinder and rewinder for excellent web tension control. |

|

|

Hot foil and embossing DC350Flex+ Wine delivers both hot foil, cold embossing, and advanced options such as foil saver and hologram register - to serve all your needs. DC350Flex+ Wine offers Electronic temperature control and BST web-guide come as standard. |

|

|

Screen printing A sophisticated high precision movable UV lamp cures exactly the thickness of varnish that is needed. |

|

|

All in one process The machine configuration also offers die cutting and slitting of the web using AutoKnives in one pass. This gives any label converter a new, more profitable way to enter luxury markets, such as high-end wine, spirits, and cosmetics. |

|

Try out our 3D product configurator and customize your finishing line according to your specific preferences and needs.

02 May 2025

28 August 2024

03 July 2024

17 January 2024

13 January 2023

06 January 2023

| Specifications | Metric | Imperial |

|---|---|---|

| Web width | 50 - 350 mm | 2 - 13.8” |

| Substrate thickness | 50 - 200 µm | 2 - 8 pt. |

| Hotstamp | ||

|

Print area (along x across machine) |

305 - 330 mm |

12.0 - 13.0” |

|

Max speed |

70 m/min |

230 ft/min |

| Screen | ||

|

Print area |

350 x 350 mm |

13.8 x 13.8” |

|

Max speed |

20 m/min |

66 ft/min |

| Die Station | ||

| Semi-rotary speed | 80 m/min | 262 ft/min |

| Full-rotary speed | 130 m/min | 426 ft/min |

| Die plate size | 50 - 558,8 mm | 2 - 22” |

| Unwinder | ||

|

Diameter max |

800 mm |

31.5” |

|

Core diameter |

76 mm |

3” |

| Rewinder | ||

|

Diameter max on dual shaft |

700 mm |

27.6” |

|

Core diameter |

76 mm |

3” |

| Flexo Station | ||

| Print cylinder size | 228,6 - 635 mm | 9 - 25” |

| Spot varnish option with registration and slow run | ||

| Slitting Station | ||

| Knife type | Pneumatic Quick CrushKnives, AutoKnives | |

| Minimum distance Quick CrushKnives | 27 mm | 1.1” |

| Minimum distance AutoKnives | 15,5 mm | 0.6” |

| Dimensions | ||

| W x D x H | 7,7 x 1,6 x 1,7 m | 25.3 x 5.2 x 5.7 ft |

Whether you do the printing or make the printers, we know that finishing is just the start of a great

brand experience for your customers.

Never hesitate to contact us for any label finishing advice or for an offer.

Contact us at:

Email: sales@gm.dk

Phone: +45 4581 2300