Ready for back-numbering systems and additional value-adding modules

Super low-tension rewinding, suitable for sensitive RFID and smart label materials

Prepared for pharmaceutical applications and validated production environments

Two-way rewinding for efficient re-inspection and roll correction

Integrated web guide to ensure consistent, high-quality roll formation

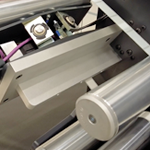

Independent tension control with separation nip for stable web handling

The LR250+ RFID is a compact inspection rewinder designed specifically for RFID and smart label production. Based on the proven LR250+ platform, this version is optimised to handle RFID inlays safely while ensuring consistent roll quality and reliable inspection during the rewinding process.

The machine is engineered to run delicate RFID materials at low tension, protecting inlays from damage and maintaining correct label orientation throughout production.

Inspection & Control

The LR250+ RFID can be supplied with camera inspection systems for printed label verification and is prepared for RFID label workflows, allowing integration with RFID checking solutions where required.

Missing labels, print defects, and positioning issues can be detected before rewinding, helping to reduce waste and ensure that only compliant RFID label rolls continue downstream.

RFID-Optimised Rewinding

Super-low tension rewind control makes the LR250+ RFID particularly suitable for smart labels and RFID inlays, where excessive tension can damage antennas or chips.

The two-way rewind system, combined with an integrated web guide, ensures even, high-quality roll formation, even on sensitive RFID constructions.

Flexibility & Options

The LR250+ RFID can be configured with:

This flexibility makes the LR250+ RFID suitable for a wide range of RFID applications including logistics, retail, industrial, and pharmaceutical labels.

|

Perfect roll quality The integrated web guide corrects the position of the web precisely and ensures excellent winding quality even with very narrow rolls. |

|

|

Full tension control Tension separation allows the setting of different values of tension of unwinder and rewinder. This is especially important with thin sensitive materials or materials on a PET liner. |

|

28 May 2025

03 October 2024

| Specifications | Metric | Imperial |

|---|---|---|

| Max web width: | 250 mm | 9.8” |

| Max speed | 200 m/min | 656 ft/min |

| Max unwind diameter | 400 mm | 15.7” |

| Max rewind diameter | 400 mm | 15.7” |

| Pneumatic shafts diameter | 25 - 120 mm | 1 - 4.7” |

| Webguide | BST Ultrasonic | |

| Inspection system | BST Tubescan, Nikka | |

| Dimensions | ||

| W x D x H | 1,7 x 0,9 x 0,9 m | 5.8 x 3.0 x 3.0 ft |

Whether you do the printing or make the printers, we know that finishing is just the start of a great

brand experience for your customers.

Never hesitate to contact us for any label finishing advice or for an offer.

Contact us at:

Email: sales@gm.dk

Phone: +45 4581 2300