A Complete and Versatile Finishing Solution for Digital Labels

DC350Flex is built for professional label printers who require a complete, flexible, and cost-efficient finishing solution for high-volume digital label production. Designed to integrate seamlessly with all major digital presses, DC350Flex delivers high performance, precision, and scalability in a compact footprint.

High-Speed, Format-Free Semi-Rotary Performance

The DC350Flex supports format-free semi-rotary die cutting at speeds of up to 120 m/min, allowing it to efficiently follow any digital press on the market. This ensures smooth inline or nearline operation with high register accuracy and consistent quality, even at higher production speeds.

In addition to die cutting, the platform supports semi-rotary spot varnishing, slitting, and dual rewind, making it a truly versatile finishing solution.

Efficient and Economical by Design

DC350Flex is engineered for cost efficiency without compromising performance. It is built using shared components from the proven DC350Mini platform, reducing the total number of parts and simplifying maintenance.

This design approach lowers manufacturing and service costs, reduces spare part inventory, and delivers a lower total cost of ownership.

Precise Web Handling and Tension Control

To ensure stable processing across a wide range of substrates, the DC350Flex features a load cell on the unwinder. This provides accurate and consistent tension control throughout production, improving register accuracy, reducing waste, and supporting reliable operation at high speeds.

Modular Platform with Upgrade Flexibility

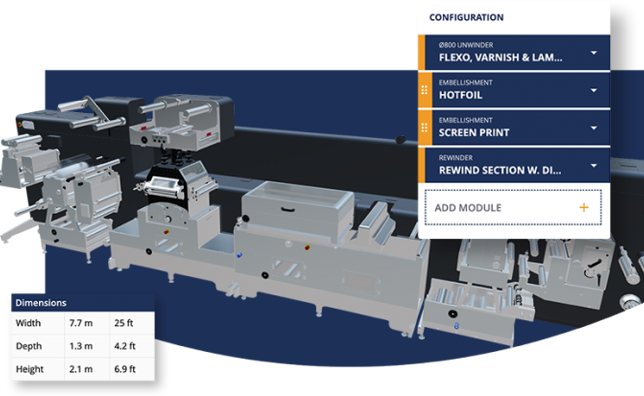

The DC350Flex is a highly modular finishing platform, allowing converters to configure the machine exactly to their production needs and upgrade it as those needs evolve.

Available value options include turret rewinding, in-register lamination (MultiLayer), AutoKnives or Quick CrushKnives, FastStrip, corona treatment, web cleaning, back scoring, and an inline buffer.

Modern User Interface and Automation

The DC350Flex features an industry-leading user interface that provides the operator with a clear, graphical representation of the machine configuration and production flow. The modern platform ensures quick setup, easy operation, and minimal downtime.

Automation features include job recall, QR code-based job setup, and automated production workflows.

Industry 4.0 Ready

DC350Flex is Industry 4.0 certified and fully prepared for inline operation with all major digital presses. With online support capabilities, remote access, and easy web-based maintenance, the system is designed for connected, data-driven production environments.

Take Your Production to the Next Level

With its combination of speed, flexibility, automation, and cost efficiency, DC350Flex is the ideal finishing platform for digital label converters looking to optimize productivity and future-proof their operation.

|

Superior end-results A cost-efficient label finisher built for volume production of added-value labels, like multi-layer labels. |

|

|

Automated operation Label production on this flexible and modern platform delivers quick setups and minimal waste. Improve productivity with less human intervention. |

|

|

Value for customers Create more value for your customers with foiling, spot varnish, and lamination. |

|

|

CERM increases efficiency GM converters are ready for integration with all digital label presses for full inline production. The possibility of integration with the CERM system increases efficiency and automates the workflow at all levels of production. |

|

Try out our 3D product configurator and customize your finishing line according to your specific preferences and needs.

02 May 2025

16 April 2025

27 February 2025

03 July 2024

04 November 2025

17 January 2024

02 April 2020

| Specifications | Metric | Imperial |

|---|---|---|

| Web width | 50 - 350 mm | 2 - 14” |

| Substrate | 50 - 200 µm | 2 - 8 pt. |

| Die Station | ||

| Max semi-rotary speed | 120 m/min | 394 ft/min |

| Max full-rotary speed | 130 m/min | 426 ft/min |

| Die plate size (repeat) | 50 - 558,8 mm | 2 - 22” |

| Unwinder | ||

| Diameter max. | 850 mm | 33.5” |

| Core diameter | 76,2 mm | 3” |

| Rewinder | ||

| Diameter max. on dual-shaft | 700 mm | 27.5” |

| Diameter max on Turret | 450 mm | 17.5” |

| Standard core diameter | 76,2 mm | 3” |

| Semi-rotary Flexo Station - Flower Style | ||

| Print cylinder size | 228,6 - 635 mm | 9 - 25” |

| Spot varnish with digital sensor register control and slow run - included | ||

| Slitting Station | ||

| Knife type | Pneumatic Quick CrushKnives, Quick Set Shear Knives, razor knives or AutoKnives | |

| Minimum distance Quick Crush | 21,5 mm | 0.85" |

| Minimum distance shear | 14 mm | 0.55” |

| Minimum distance AutoKnives | 15,5 mm | 0.61” |

| Dimensions | ||

| W x D x H | 5.90 × 2.24 × 1.66 m | 19.35 × 7.35 × 5.44 ft |

"

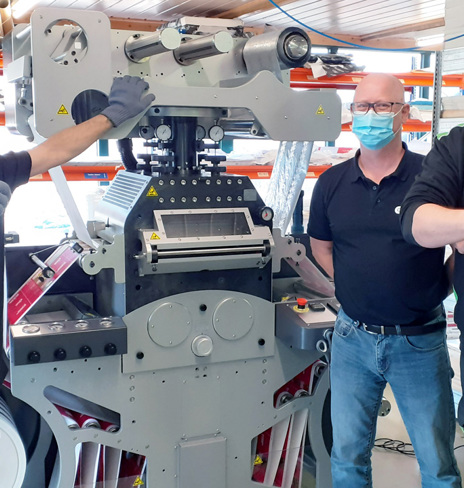

Mischa Barthel

Managing Partner

Barthel Group

"

To complement its fleet of digital label printing equipment, Leapin’ Lizard Labels has teamed with a host of suppliers to round out the business. On the finishing side the company invested in a GM DC330 finishing unit.

"

Druckerei W. Medinger GmbH's ambition is to serve high-quality wine-label customers from their new HOTFB330.

"

Vinograf Chile has recently added a new DC350Mini to its production line, helping them increase the production premium label manufacturing process for the wine market.

Whether you do the printing or make the printers, we know that finishing is just the start of a great

brand experience for your customers.

Never hesitate to contact us for any label finishing advice or for an offer.

Contact us at:

Email: sales@gm.dk

Phone: +45 4581 2300