Hybrid finishing solutions – Co-Engineered for Flexibility, Precision, and Productivity

Successful hybrid label production requires more than advanced hardware. It depends on close collaboration, deep technical alignment, and the right OEM partnerships.

By working closely with leading press manufacturers such as HP Indigo, SCREEN, Domino, Konica Minolta, Epson, Xeikon, and others, we have developed hybrid finishing solutions that integrate seamlessly, perform reliably, and deliver real, measurable production value.

Our die-cutting and flexo station finishing options are developed and powered by GM, bringing proven finishing expertise into a fully optimized OEM configuration. This co-engineered approach ensures printing and finishing function as one cohesive system—maximizing flexibility, precision, and overall productivity rather than operating as disconnected components.

OEM-Driven Finishing Development

Co-Engineered Solutions - Finishing units designed specifically to match press performance, web control, and production speed.

Die Cutting Excellence - Precision rotary die cutting for accurate registration and clean label edges.

Flexo Station Versatility - Inline flexo units for varnishing, coatings, and functional applications.

Seamless Integration - Mechanical, electronic, and software-level compatibility for smooth operation.

Proven Industrial Reliability - Robust construction and stable performance in demanding production environments.

The Value of the Right Partner

By choosing GM as the finishing technology partner, OEM solutions benefit from decades of converting expertise, modular engineering, and production-focused design. This approach shortens development cycles, reduces risk, and delivers a finishing solution that is fully aligned with market needs.

The result is a true hybrid print-and-finish system-developed through cooperation, strengthened by OEM integration, and powered by finishing technology built for performance and scalability.

|

Hybrid finishing performance A flexible hybrid solution delivering consistent, high-quality results for both short and long runs. |

|

|

Automated operation Fast setup, smooth changeovers, and minimal waste with reduced operator intervention. |

|

|

Addded value for customers Enable premium labels with precision die cutting and inline flexo varnish and coatings. |

|

|

OEM integration powered by GM Die cutting and flexo stations developed and powered by GM Finishing, ready for inline production and workflow integratio |

|

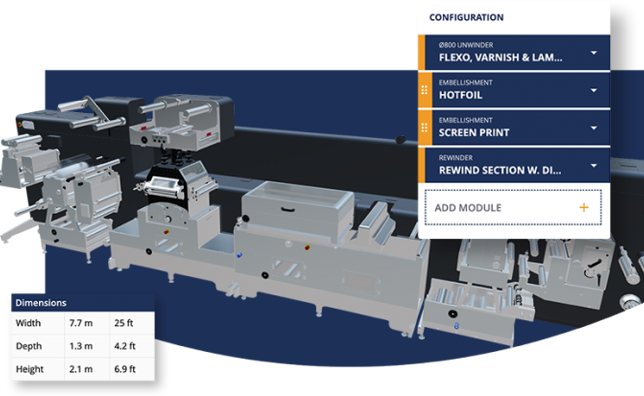

Try out our 3D product configurator and customize your finishing line according to your specific preferences and needs.

06 January 2026

| Specifications | Metric | Imperial |

|---|---|---|

| Web width | 50 - 350 mm | 2 - 13.8” |

| Substrate | 50 - 200 µm | 2 - 7.9 pt. |

| Die Station | ||

| Max semi-rotary speed | 80 m/min | 262 ft/min |

| Max full-rotary speed | 130 m/min | 426 ft/min |

| Die plate size (repeat) | 50 - 558,8 mm | 2 - 22” |

| Unwinder | ||

| Diameter max. | 800 mm | 31.5” |

| Core diameter | 76,2 mm | 3” |

| Rewinder | ||

| Diameter max. on dual-shaft | 700 mm | 27.5” |

| Diameter max on Turret | 450 mm | 17.5” |

| Standard core diameter | 76,2 mm | 3” |

| Semi-rotary Flexo Station - Flower Style | ||

| Print cylinder size | 228,6 - 635 mm | 9 - 25” |

| Spot varnish with digital sensor register control and slow run included | ||

| Slitting Station | ||

| Knife type | Pneumatic Quick CrushKnives, shear, or AutoKnives | |

| Minimum distance Quick Crush | 27 mm | 1.1” |

| Minimum distance shear | 14 mm | 0.55” |

| Minimum distance AutoKnives | 15,5 mm | 0.61” |

| Dimensions | ||

| W x D x H | 4,0 x 1,6 x 1,7 m | 13.1 x 5.3 x 5.7 ft |

Whether you do the printing or make the printers, we know that finishing is just the start of a great

brand experience for your customers.

Never hesitate to contact us for any label finishing advice or for an offer.

Contact us at:

Email: sales@gm.dk

Phone: +45 4581 2300