DC350Flex+ with the booklet module is a special finishing line that brings together GM’s modular converting platform, Longford´s Booklet Feeder and Nordson’s advanced glueing systems, enabling the production of complex labels – including multi-layer, multi-page formats.

Featuring high-speed, two die-cutting stations, curved lamination, and slitting, this modular platform can be upgraded easily with value-added options, including digital embellishment (DVM350), varnish flexo station, laser die cutter, and more.

Whether you’re in pharma, agrochemicals, food, or cosmetics, booklet labels offer more space without sacrificing shelf appeal – and we make producing them simple.

The DC350Flex+ platform was born to be modular, so if the market changes, new modules can be retrofitted quickly.

Even third-party technology, such as a digital spot varnish module, can be integrated for true hybrid production.

Bespoke client options are available on the PLUS series.

DC350Flex+ is Industry 4.0 certified and fully compatible with all major digital presses.

This unique modular finishing platform is redefining standards in the label industry, empowering you to expand into new markets.

Booklet labels are ideal when you need to include:

|

Modular design Easy integration with the DC350Flex line |

|

|

High-Speed Precision Feeding Feeds products from 22x51 mm up to 6 mm thick, at speeds up to 35,000 pieces/hour. |

|

|

Adapts to all your needs Whether you need to die-cut labels, insert booklets, or create high-quality embellishments with digital varnish, this machine offers maximum modularity. |

|

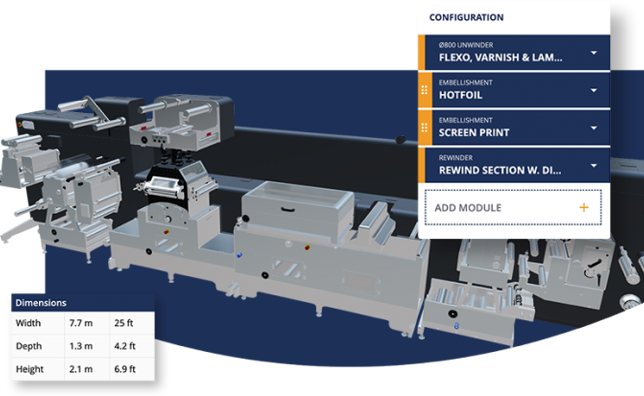

Try out our 3D product configurator and customize your finishing line according to your specific preferences and needs.

02 May 2025

| Specifications | Metric | Imperial |

|---|---|---|

| Web width | 50 – 350 mm | 2 – 13.8” |

| Substrate thickness | 50 – 200 μm | 2 – 8 pt. |

| Die Station | ||

| Max semi-rotary speed | 80 m/min | 262 ft/min |

| Max full-rotary speed | 130 m/min | 426 ft/min |

| Die plate size | 50 – 558,8 mm | 2 – 22” |

| Unwinder | ||

| Diameter max. | 800 mm | 31.5” |

| Core diameter | 76,2 mm | 3” |

| Rewinder | ||

| Diameter max on dual shaft | 700 mm | 27.5” |

| Diameter max on turret | 450 mm | 17.5” |

| Standard core diameter | 76,2 mm | 3” |

| Waste matrix rewinder diameter | Up to 800 mm on request | Up to 31.5” on request |

| Semi-rotary Flexo Station - Flower style | ||

| Print cylinder size | 228,6 – 635 mm | 9 – 25” |

| Spot varnish with digital sensor register control and slow run included | ||

| Slitting Station | ||

| Knife type | Pneumatic Quick CrushKnives, shear, or AutoKnives | |

| Minimum distance Quick Crush | 27 mm | 1.1” |

| Minimum distance shear | 14 mm | 0.55” |

| Minimum distance AutoKnives | 15,5 mm | 0.61” |

| Dimensions | ||

| W x D x H | Depends on configuration | |

"

Mischa Barthel

Managing Partner

Barthel Group

"

Stefan Pscherer

Managing Director

Pscherer GmbH

Whether you do the printing or make the printers, we know that finishing is just the start of a great

brand experience for your customers.

Never hesitate to contact us for any label finishing advice or for an offer.

Contact us at:

Email: sales@gm.dk

Phone: +45 4581 2300