We put your revenue first

For over 40 years, GM has engineered best-in-class solutions for the self-adhesive label converting, finishing, and flexible packaging industry. Machines that are faster, smarter, tougher, easier – backed

by peerless service and support.

Since we began, our company has pursued one single-minded mission: to deliver better value for our label printer and OEM customers than any other provider.

We focus on your benefits and help you stay ahead

Features are great, benefits are better. We focus on innovative solutions that deliver measurably better results – so you don’t just deliver a more efficient service to your customers, you deliver a more valuable brand experience.

The competition never stops, which is why we keep innovating. We offer more advanced technology so you stay in the lead – from fully automated converting lines to new printing processes, protected by built-in 24/7 support.

3D Machine Configurator

Try our 3D product configurator to customize your finishing line to your exact needs. Simplify product and module selection, get a realistic preview, and receive fast, accurate pricing from our sales team.

Compact Solutions for Precision Finishing

Discover GM Finishing's versatile finishing solutions: the DC350nano and DC350mini. The DC350nano offers a compact, cost-effective solution ideal for short-run jobs, combining lamination, slitting, and die-cutting in one efficient system.

For increased flexibility and advanced features, the DC350mini delivers powerful performance with a modular design, perfect for high-quality labels and packaging finishes. Both machines ensure precision, ease of use, and outstanding results — tailored to meet your production needs.

Short-run Labels

Short-run label production involves printing small quantities of labels—typically from a few hundred to a few thousand units—offering businesses flexibility and cost-effectiveness. This approach enables rapid response to market changes, product variations, and promotional needs without the long lead times or high setup costs associated with traditional printing methods.

Digital printing technology has revolutionized this process by allowing high-quality, on-demand printing with variable data, vibrant colors, and intricate designs. This is particularly beneficial for industries like craft beverages, cosmetics, and health products, where customization and quick turnaround are essential.

Hot Foil

The HF350 is a versatile hot stamping and embossing machine designed to enhance label aesthetics with metallic effects and tactile finishes. It supports both hot foil and cold embossing, allowing for intricate designs and a premium appearance.

Features like servo-register, BST web guide, and an intuitive touchscreen interface ensure precise operation and ease of use. Ideal for industries such as wine, cosmetics, and gourmet foods, the HF350 helps brands create standout labels that capture consumer attention.

Premium Labels

More and more producers differentiate themselves by applying labels with very advanced designs and sophisticated features combined with easy brand recognition. The bottle must catch the buyer’s eye when browsing the shelves

One of the elements, that makes this segment challenging to many printers, is the use of special substrates. A wine label will often be printed on textured, non-coated paper. These porous vintage papers call for both screen and especially hot stamping methods.

Laser Die-Cutting

The LC350 is a compact, fully digital laser finishing machine designed for efficient label production. It offers tool-free operation with near-zero setup time, enabling quick job changes and reducing downtime. The system supports various laser processes—including kiss-cutting, slitting, perforating, and ablating—on materials commonly used in the label industry.

Standard features include laser die-cutting, varnishing, slitting, and dual rewind, all managed through a fully digital positioning system for precise register and cut-depth control. The LC350 is compatible with GM converting lines like the DC350Flex+, requiring only minor modifications.

RFID Labels for Precision and Efficiency

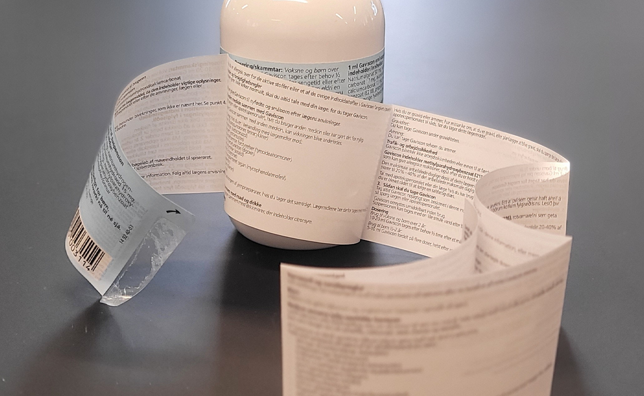

Booklet Labels

Booklet labels (ECLs) add space for info without clutter. Used in pharma, agrochemicals, cosmetics, and food, they ensure compliance and offer marketing options.

The GM Booklet Module’s curved lamination prevents wrinkles, ensuring durability and a flawless finish.

Pharma Labels

Consistency, traceability, and compliance are critical for pharmaceutical labels, which require detailed info, codes, and security features. GM ensures fault-free rolls with advanced camera inspection during converting.

With 40+ years of expertise, GM provides quality control solutions, from the LR250+ inspection rewinder to the high-speed SR350/550. The new SR350/550 Pharma model features automatic inspection and reinspection at up to 300 m/min.

Key facts

0%

World wide

0.000

Installed machines

0m³

Production facility in Denmark