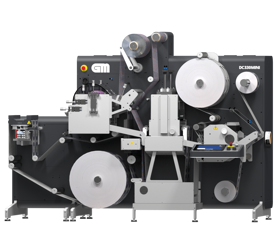

DC330Mini provides full flexibility in finishing and die-cutting, you can even print an extra color – the sky really is the limit with this powerful tool.

- Fastest ROI in the market

- High performance, precision cutting and ultrashort web path

- Works inline with any digital press

- Works inline with GM hotfoil and screen embellishment units

- Train an operator in just one day

- Online support and remote diagnostics

- High performance - up to 80 m/min semi-rotary (optional)

- Industry 4.0 ready

All-in-one compact solution

DC330Mini is developed in a small footprint to minimize waste and maximize productivity.

DC330Mini provides UV flexo varnish, lamination, cold-foil, die cutting and slit and dual rewind on one single compact platform.

The drive train in the DC330Mini is completely servo driven offering low maintenance servo-driven tension control and good registration.

Videos

01 February 2023

DC330Mini is a high-performance, all-in-one compact label finisher

12 December 2022

DC330 Mini a high-performance, all-in-one compact label finisher

12 December 2022

Ultra compact die cutter

12 December 2022

The fastest small footprint machine in the market

Install easily and learn quickly

The DC330Mine is so easy to install - that if needed you can do it on your own! We will guide you all the way over a video link. This has been a unique advantage during the lockdown in many regions in the last months.

Join our online video library of easy-to-understand tech videos on how to operate the machine. Learn the best tricks in die cutting & varnish to make your labels stand out one step ahead of the competition.

- Online Support - easy web access and maintenance

- Inline options for any digital press

- Easy to use and learn

Add the unique and exclusive look to your labels

The build-in flexo varnish station can do much more than "just flood varnish"!

Create amazing effects with silver, gold and other metallic colours for eye-catching labels.

Combine the varnish with a special foil for an amazing super gloss effect. Apply multi-colour hologram foils with 3D effect in the Cast and Cure process to make the product shine. See the picture above!

Cases

"

SONNENTOR has been a very interesting customer – due to the fact that their core business is food and NOT label/packaging. In addition, their approach for local supply chain, green production, and their aim of limiting transport necessities was an eye-opener as well. This will definitely have impact on our own dealing with resources in the future.

Andreas Höfner

Executive Partner

Stepan GmbH

"

Grace Imaging serves the top-tier wine & spirits clients who have an extremely high demand for quality and customization. To be able to stay on top of this segment the company depends on cutting-edge equipment. Today Grace Imaging has 5 GM machines which have played an important part in their success and growth.

Key facts

0%

World wide

0.000

Installed machines

0m³

Production facility in Denmark